Textilveredlung

Foil printing in flex printing

Flex printing is ideal for single-color lettering or for motifs with a maximum of 3 colors.

Color gradients cannot be displayed. This method is ideal for numbers, fonts and simple objects. Motifs are applied to the substrate using a thin foil. A transfer press is used for this and works with high pressure and heat.

• Possible from one article

• Durable, resilient and washable

• Ideal for writing on sports textiles

• No setup costs

• Applicable to polyester, cotton, nylon and mixed fabrics

• Short production time

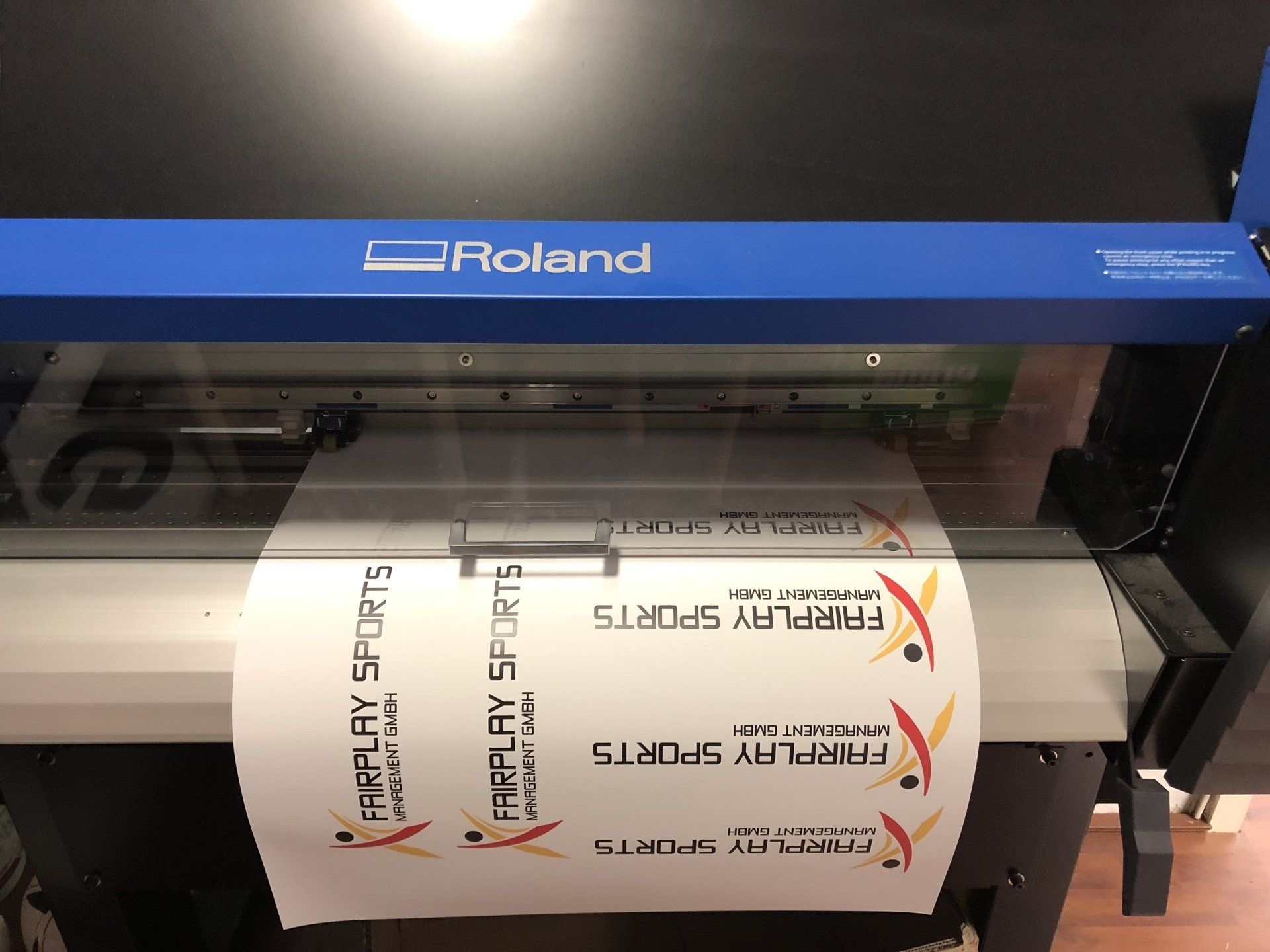

Digital Print Transfer

There is no direct printing on the textiles, but via transfer foils.

With digital transfers, particularly fine details and color gradients can be reproduced.

Printing with transfer foils via digital printing is particularly useful for smaller runs. The motifs are pressed onto the textiles using a transfer press.

• Possible from one article

• Several colors and color gradients can be displayed

• Wash resistance and color fastness are very high here

• No setup costs

• Applicable to polyester, cotton, nylon and mixed fabrics

• Short production time

screen printing

Screen printing results in high fixed costs, but cheap printing costs. This technique is therefore used in larger quantities.

The color imprint is done directly on the material. As a result, the motif is hardly noticeable. For larger runs, this process is very economical and delivers the best results. In addition, almost all textiles can be printed with this process.

• Useful for several items

• Very durable and hard-wearing, as well as being washable and ironable

• Radiant colors

• High setup costs (screens and stencils)

• Applicable to polyester, cotton, nylon and mixed fabrics. Except softshell and fleece.

• Allow for lead time and longer production time

Direct insertion

The highest quality and at the same time one of the oldest techniques for finishing textiles. Especially with the high-quality appearance, the embroidery can set itself apart from the other types of finishing. In addition, embroidered textiles can be washed without any problems and are significantly more durable than other types of finishing.

Detailed motifs and color gradients must be simplified so that embroidery is possible. Embroidery is possible on all types of textiles.

• Useful for several items

• Very durable and resistant

• Extremely high wash resistance and non-iron

• Possible on almost any textile

• High fixed costs (one-off costs) for creating an embroidery program

• Allow for lead time and longer production time

emblems and patches

Patches and emblems can be made with any imaginable motif. Contours, color gradients and the finest lines are easy to display. Patches and emblems can be produced as patches or, as is more common in textile finishing, with an iron-on coating. The emblem or the patch is applied to the textile with a heat press using pressure and heat.

We can offer you emblems and patches embroidered, woven or printed.

• Possible from several articles

• Very durable and resistant

• High wash resistance and non-iron

• Possible on almost any textile

• No setup costs

• Allow for lead time and longer production time, approx. 6 weeks

Satin patches with 3D optics

The noblest method for the implementation of your coat of arms. Almost all motifs can be displayed here. Multi-colored motifs are printed on a satin base, true to detail and colour, and the patch is finished with an embroidered border. A 3D effect is used for this. On the back is an iron-on coating to apply the patch to the textile with a transfer press under pressure and heat.

• Only possible from 150 articles

• Very durable and resistant

• High wash resistance and non-iron

• Possible on almost any textile

• No setup costs

• Allow for lead time and longer production time, approx. 6 weeks

What files do we need

Vectorized graphics, e.g. B. in the formats EPS, AI, PDF (vector-based), etc.

We would also be happy to advise you on all types of textile printing and the advantages and disadvantages of your individual garments.

Of course, we will store your ordered emblems or patches free of charge and apply them as required.

How does textile finishing work?

1. You tell us your finishing requirements and send us the files to be printed

2. How to create a proof for you

3. Only after your approval do we start with the refinement

If you have any questions, we are happy to help you personally.